Spare parts for rotating compressor and other equipment from STASSKOL

100 Years of Experience

in Sealing Technologies and Applications

Main customers in the field of Rotating Equipment's that we are working with:

- Siemens

- Borsig ZM

- Atlas Copco

- Neuman & Esser

- Howden

- Kirloskar

- Piller

- FIMA

- Reitz

- TLT

- Bühler

- LTG

- ANOD

- Flottweg

- Team Turbo

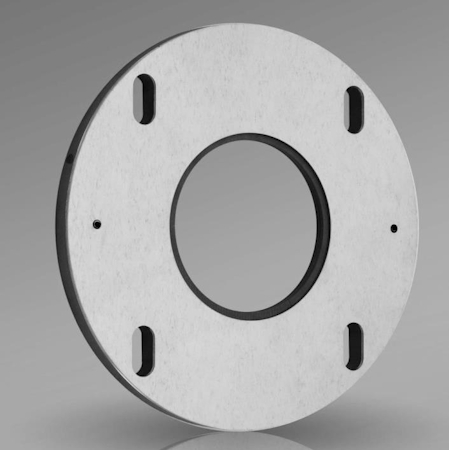

Carbon Ring Seal – Split Housing Designs

Radially cut ring seal SDW20

Features

- Low friction

- Low heat generation

- Long service intervals

- Small self-adjusting sealing gap

- Customized purge gas or grease connection

Materials

- Sealing rings made of carbon or PTFE

- Housings made of 1.4021, 1.4571 or others

Applications

- Blowers, Turbo-Compressors, Steam Turbines, Mixers

- Vacuum up to 25 bar

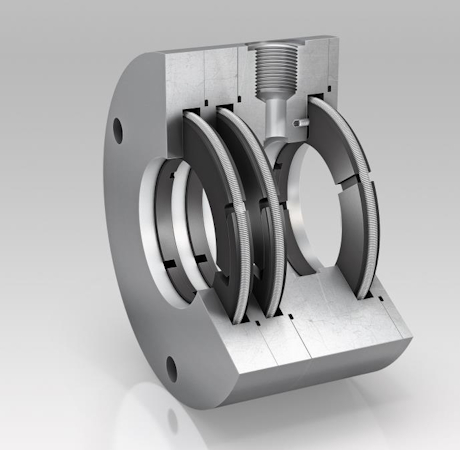

Carbon Ring Seal – Split Housing Designs

Overlapped sealing ring seal SDW50

Features

- Gastight overlapped gaps

- High sealing efficiency

- Compensation of axial and radial shaft movement

Materials

- Sealing rings made of carbon or PTFE

- Housings made of 1.4021, 1.4571 or others

Applications

- Blowers, Mixers

- Vacuum up to 3 bar

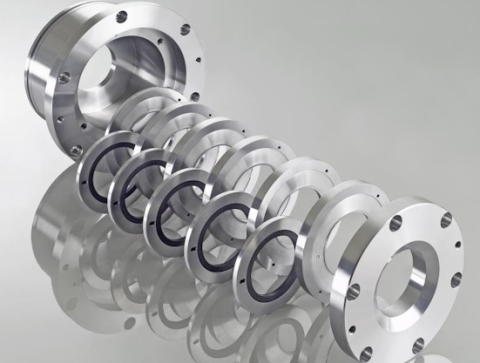

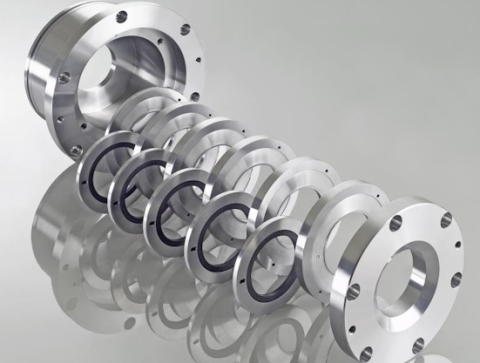

Carbon Ring Seal – Cup Designs

Radially cut ring seal SDK30

Features

- Low friction

- Low heat generation

- Long service intervals

- Small self-adjusting sealing gap

- Customized purge gas or grease connection

Materials

- Sealing rings made of carbon or PTFE

- Housings made of 1.4021, 1.4571 or others

Applications

- Blowers, Ventilators, Mixers

- Vacuum up to 3 bar

Carbon Ring Seal – Cup Designs

Radially cut ring seal SDK31

Features

- Low friction

- Low heat generation

- Long service intervals

- Small self-adjusting sealing gap

- Inexpensive

- Short term delivery as parts are on stock

Materials

- Sealing rings made of carbon or PTFE

- Housings made of 1.4571 or others

Applications

- Blowers, Ventilators, Mixers

- Vacuum up to 1,5 bar

Carbon Ring Seal – Cup Designs

Overlapped ring seal SDK60

Features

- Gastight overlapped gaps

- High sealing efficiency

- Compensation of axial and radial shaft movement

Materials

- Sealing rings made of carbon or PTFE

- Housings made of 1.4021, 1.4571 or others

Applications

- Blowers, Ventilators, Mixers

- Vacuum up to 3 bar

Carbon Ring Seal – Cup Designs

Radially cut ring seal SDK40

Features

- Low friction

- Low heat generation

- Long service intervals

- Small self-adjusting sealing gap

Materials

- Sealing rings made of carbon

- Housings made of 1.4021, 1.4571 or others

Applications

- Gas- and Steam Turbines, Turbo compressors, Mixers, Blowers

- Vacuum up to 50 bar

Carbon Ring Seal – Cup Designs

Solid ring seal SDK80

Features

- Contactless, no friction

- No heat generation

- Long service intervals

- Small sealing gap

- Solid rings, bandaging depends on specific application

Materials

- Sealing rings made of carbon

- Housings made of 1.4021, 1.4571 or others

- Bandages made of Titanium

Applications

- Gas- and Steam Turbines, Turbo compressors

- Vacuum up to 100 bar

Carbon Ring Seal – Cup Designs

Solid ring seal SDS100

Features

- Contactless, no friction

- No heat generation

- Long service intervals

- Small sealing gap

- Solid rings, bandaging depends on specific application

- High sealing efficiency and compact design

Materials

- Sealing rings made of carbon

- Housings made of 1.4021, 1.4571 or others

- Bandages made of Titanium

Applications

- Gas- and Steam Turbines, Turbo compressors

- Vacuum up to 150 bar

Labyrinth Seals

Labyrinth Seal SDL90

Features

- Contactless, no friction

- No heat generation

- Long service intervals

- Internal bandage made of carbon allowing small sealing gap

Materials

- Shaft and sleeve and housing made of 1.4301, 1.4021, 1.4571 or others

- Bandages made of carbon

Applications

- Gas- and Steam Turbines, Blowers

- Vacuum up to 100 bar

Labyrinth Seals – Split Housing Designs

Labyrinth Seal SDL90

Features

- Contactless, no friction

- No heat generation

- Long service intervals

- Internal bandage made of carbon allowing small sealing gap

Materials

- All in one made of PEEK or PTFE

Applications

- Blowers, Mixers

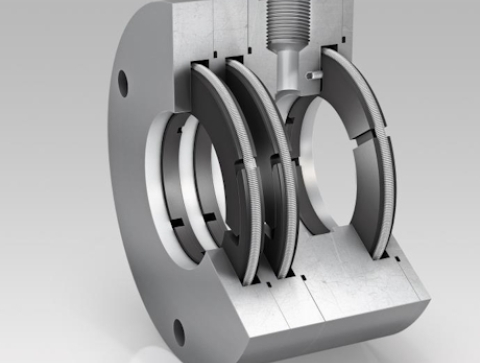

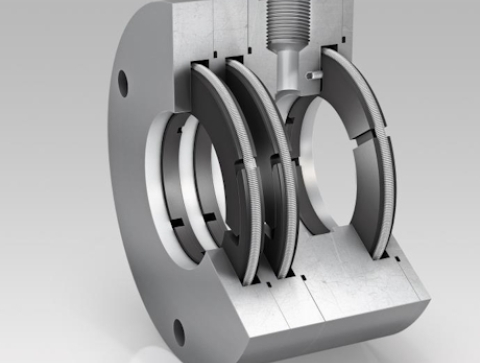

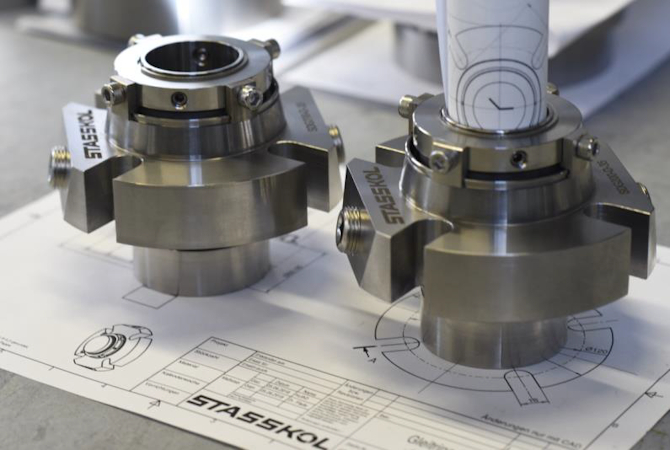

Mechanical Seals SDG 100 Series

Single-acting seal SDG100 E

Features

- Cartridge design for easy installation

- Available with customized connections for flush

- Quench version SDG200 Q also available

- Shaft diameter 25mm…100mm

Materials

- Face ring: Carbon, SiC, WC

- Mating ring: SiC, WC

- Secondary seals: NBR, EPDM, Viton, Kalrez etc.

- Metal parts, springs:1.4401 (SS316), Hastelloy C

Applications

- Pumps

- Up to 25 bar

- -40°C …220°C

Mechanical Seals SDG 100 Series

Double-acting seal SDG100 D

Features

- Cartridge design for easy installation

- Available with customized connections for flush and buffer liquid

- Shaft diameter 25mm…100mm

Materials

- Face ring: Carbon, SiC, WC

- Mating ring: SiC, WC

- Secondary seals: NBR, EPDM, Viton, Kalrez etc.

- Metal parts, springs:1.4401 (SS316), Hastelloy C

Applications

- Pumps

- Up to 25 bar

- -40°C …220°C

Here you can download additional materials for STASSKOL products