Compressors are technological machines for compressing certain volumes of air or process gases and supplying them under a given pressure to the process or the output discharge pipeline. Compressor equipment is widely used in technological processes of the oil and gas, chemical, metallurgical and general industries.

Basically, according to the principle of operation, compressors can be divided into centrifugal and positive displacement. Positive displacement, in turn, can be divided into piston, screw, rotary vane and membrane. Of course, modern compressors have many varieties and technical features, for example, single or multi-stage, oil or oil-free, driven by electric motors, gas turbines or internal combustion engines. As a rule, compressor units are complex systems, including the compressor itself, a set of auxiliary equipment and systems that allow you to control operating parameters and protect the main machine from operating errors or from emergency operating modes.

Our company specializes in the correct selection and assembly of special technological compressors for various gases. This is a rather responsible and labor-intensive process, the effectiveness of which depends largely on understanding the technological process, gas properties, input data and Customer requirements. Our partners, foreign manufacturers, NEUMAN & ESSER, HOFER, with the help of our managers, are ready to provide advice and select the optimal solution, both in terms of compressor design, energy consumption and the total cost of ownership of the machine throughout its entire life cycle.

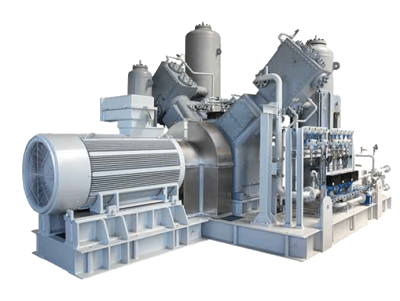

Piston compressors NEUMAN & ESSER (NEA) offers the best solutions for all customer requirements. The NEA compressor portfolio includes various shapes and designs: horizontal "boxer" design, vertical piston compressor and V-version piston compressor. Diaphragm compressors from HOFER complete the compressors program. Customers are available in more than 8 different crankcase sizes according to API 618, as well as many other crankcase sizes according to NEA.

The gas-tight design guarantees leak-free gas compression. The main data of NEA compressors include discharge pressures of up to 1000 bar, effective suction volumes of up to 150,000 m3/h and drive power from 5 kW to 30 MW, the widest power range on the piston compressor market. The performance range is complemented by a combination, i.e. a combination of different types of compressor designs.

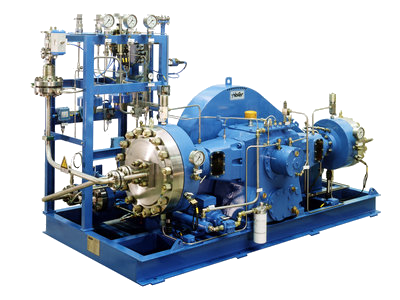

HOFER diaphragm compressors are completely sealed and leak-free. They are particularly suitable for gases of the highest purity, as well as for explosive, toxic and expensive gases.

HOFER diaphragm compressors provide reliable compression of various gases such as hydrogen, helium, argon, ethylene, fluorine, hydrogen sulfide, chlorine, monosilane or nitrogen trifluoride.

HOFER diaphragm compressors are typically used for filling storage tanks, for feeding into continuous processes or as gas circulation compressors.

The design of HOFER diaphragm compressors makes these machines exceptionally safe, reliable and easy to maintain. As a rule, diaphragm compressors are supplied as complete units, including base frame, power unit, pulsation dampers, coolers, valves with automatic or manual control, instruments and, optionally, a control unit. It is also possible to supply diaphragm compressors without peripheral equipment, ready to be installed in your system.

All HOFER diaphragm compressors undergo a load test run at the factory, during which the operating data is recorded and documented.