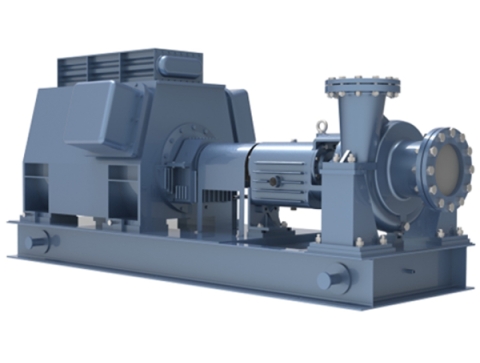

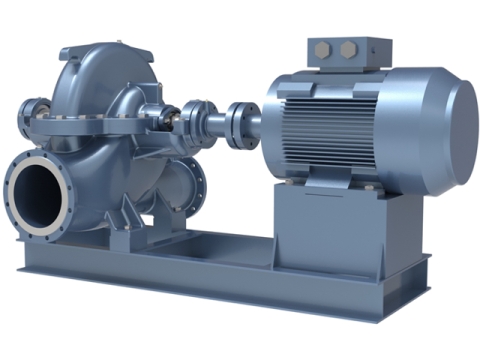

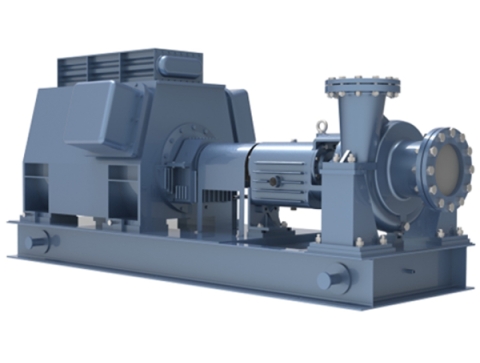

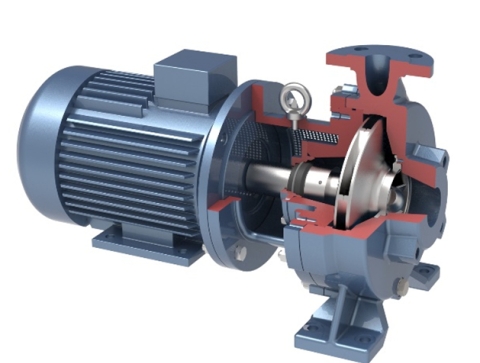

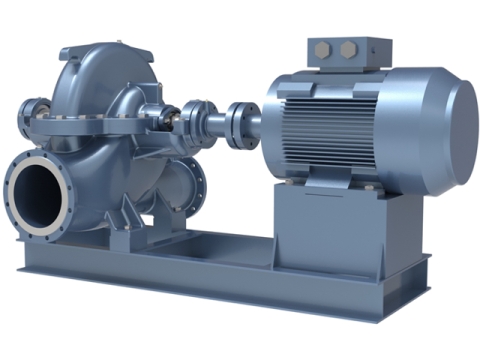

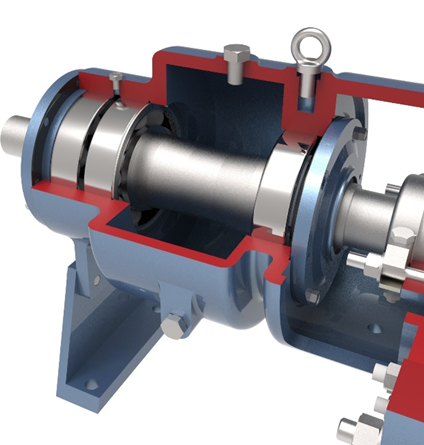

Prime Pump - Unified centrifugal pumps for industry applications.

- Heavy-duty pump.

High-quality performance, reliability, simplicity, quick maintenance

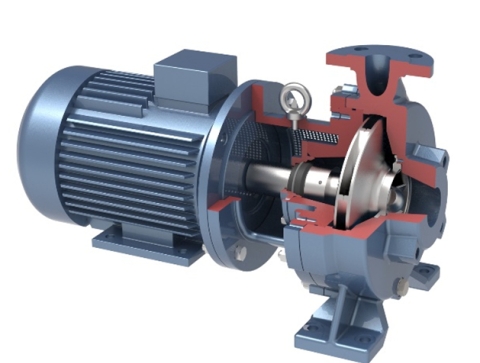

- Unified design.

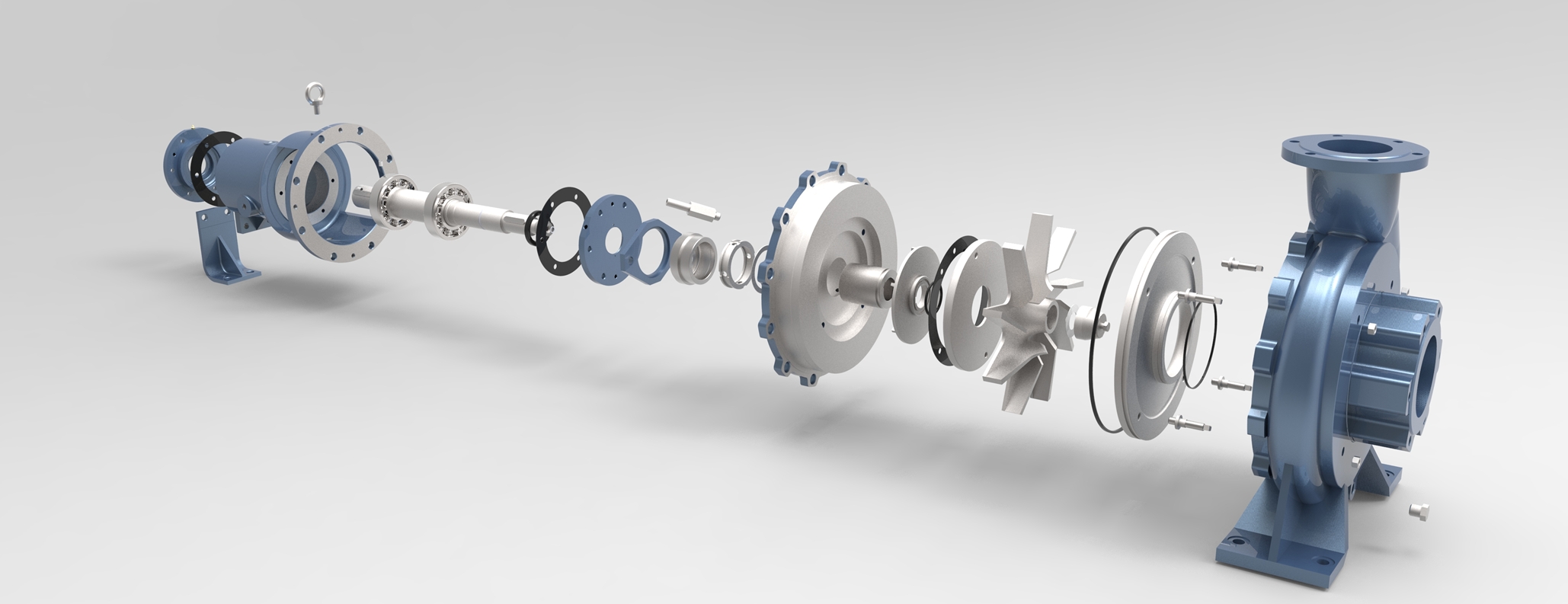

Use of block-modular design technology allows various components to be used on one pump base. (types of impellers, types of seals, types of bearings)

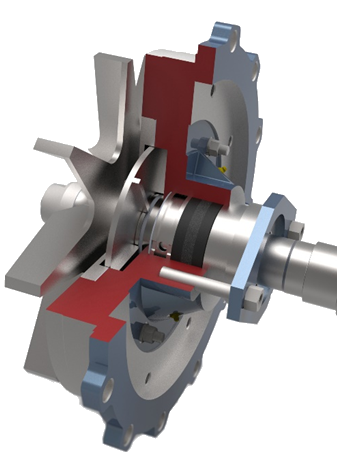

- Adjustable armor disk.

The armor disk protects the housing from wear, and when configured with an open impeller, allows you to adjust the gap between the impeller and the armor disk.

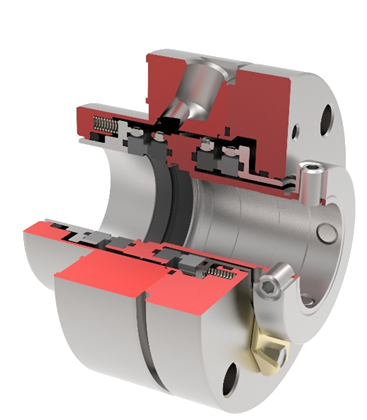

- Reliable seal.

Seal at the customer's choice. Single end, double end, dynamic, gland.

- Material design.

Possibility of manufacturing the flow part of the pump in various material designs.

Advantages of the modular design of pumps type LC / LF

- Reduction of weight and dimensions

- Elimination of oil leaks from the bearing housing;

- Sealing of rotor parts to prevent the pumped product from getting between the impeller, sleeve, impeller and shaft (improved maintainability);

- Provision of adjustment of the axial clearance between the open impeller and the fairing without disassembling the pump;

- Unloading of axial force and unloading of pressure on the end seal due to the use of a dynamic seal;

- Block-modular design (selection of pump elements depending on the Customer's needs).

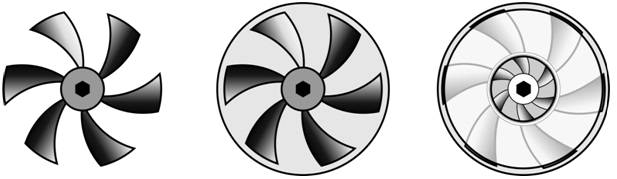

Closed impeller type

- High efficiency

- High strength

- Low volume losses (flow from the wheel outlet to the wheel inlet)

- High anti-cavitation characteristics

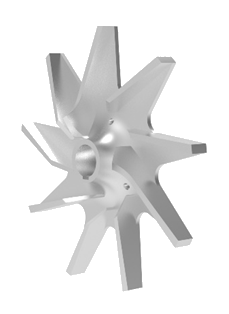

Open impeller type

- Abrasion resistant

- Resistant to deposits

- Non-clogging

Designed for:

- Viscous media

- Crystallizing media

- Gas-containing media

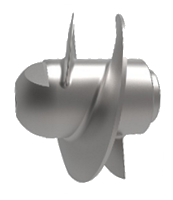

Pre-included inducer

- Used for hot liquids

- For pumping liquids with a vacuum at the inlet

- Can be installed before both an open and a closed wheel

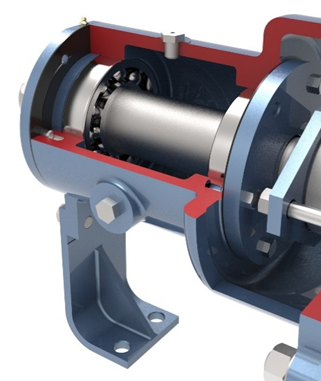

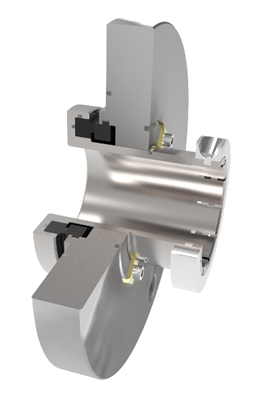

Type 1 - Standard

- Radial ball bearings

- Lubrication type: grease or oil

- Minimum MTBF 18,000 hours

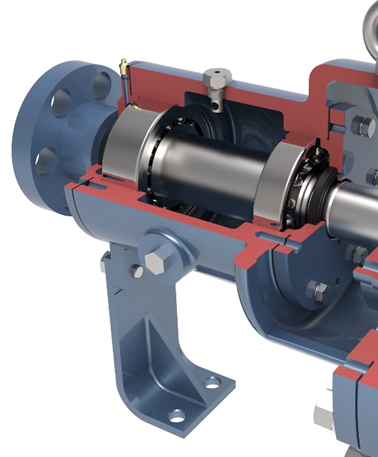

Type 2 - Reinforced

- Radial ball bearing

- Angular contact, double ball bearing

- Reinforced shaft

- Lubrication type: plastic or oil

- Minimum time between failures 25,000 hours

Type 3 - Heavy duty

- Radial ball bearing / roller bearing

- Two radial thrust ball bearings

- Reinforced shaft

- Lubrication type: grease or oil

- Minimum MTBF of 35,000 hours

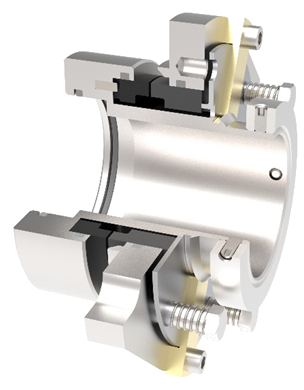

Hydrodynamic

- Tightness

- Resistance to dry running

- Work with abrasive media

- Work with aggressive media

- Work with crystallizing media

- Works without flushing / cooling

- Average service life of 7 – 10 years

- Repairability

Single mech seal cartridge type

- Tightness

- Work with aggressive environments

- Convenient and quick replacement

- Repairability

Single mech seal with external springs

- Tightness

- Work with abrasive environments

- Work with aggressive environments

- Work with crystallizing environments

- Convenient and quick replacement

- Repairability

Cartridge double mechanical mech seal

- Tightness

- Dry-running resistance

- Operation with vacuum at the inlet

- Operation with high temperature

- Operation with abrasive media

- Operation with aggressive media

- Operation with crystallizing media

- Convenient and quick replacement

- Possibility of equipping with a thermosiphon system

- Repairability

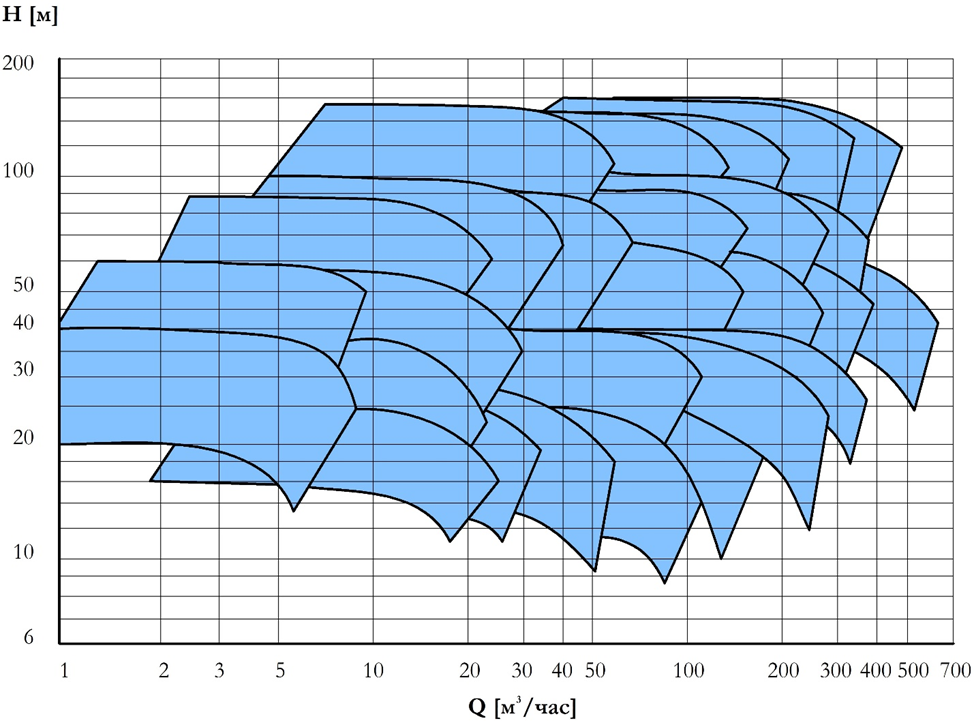

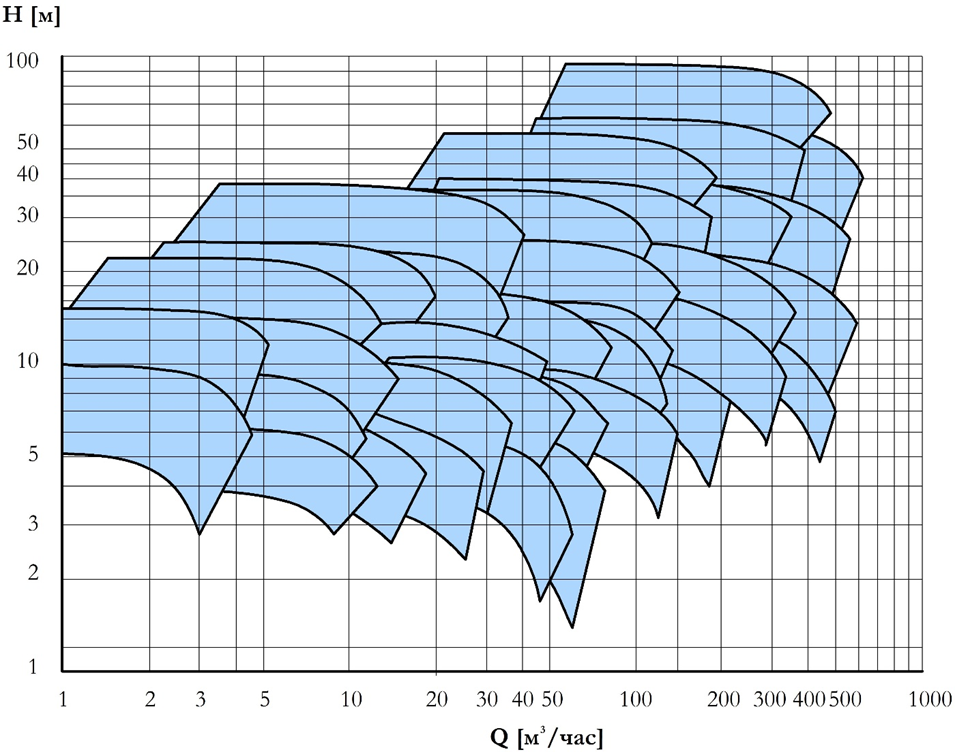

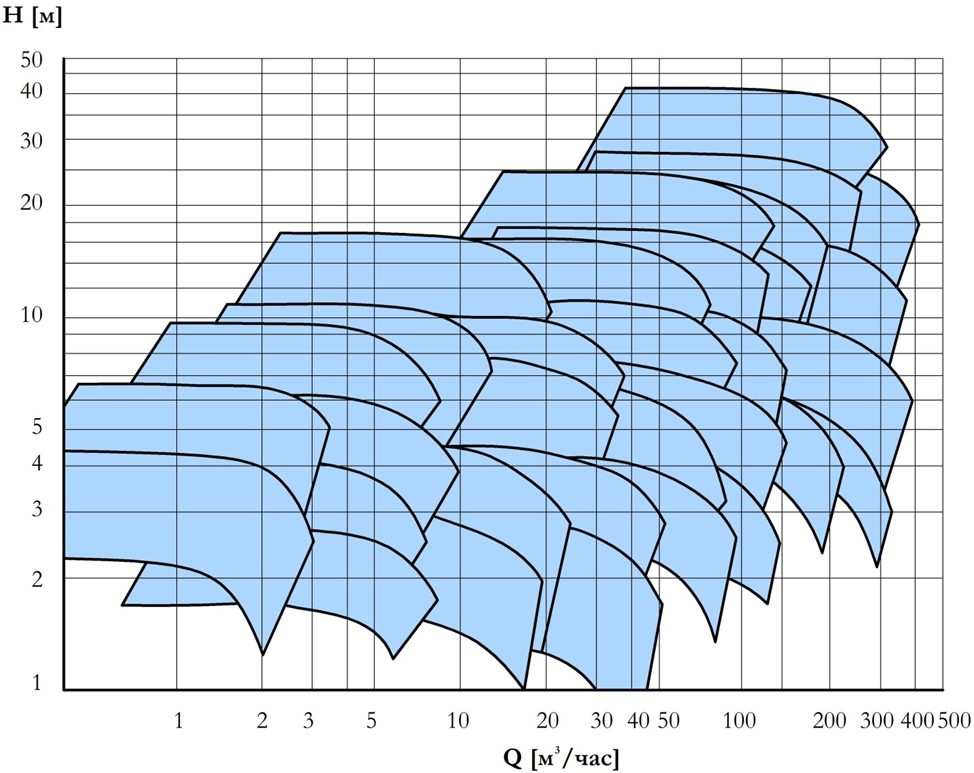

Main characteristics.

| FOR PUMPS IN MONOBLOCK DESIGN | FOR PUMPS INSTALLED ON BASE PLATE |

|---|---|

|

|

Characteristic fields 2900 / 1450 / 960 rpm

2900 rpm

1450 rpm

960 rpm

Materials of construction.

Depending on the working environment

- Cast iron Sch20

- Steel 25L

- Stainless steel 20X13

- Stainless steel 12X18N10T

- Stainless steel 06XN28MDT

- Titanium alloy VT 1-0

Main areas of application |

|||

|---|---|---|---|

| Clean liquids | Food industry | Chemistry | Oil refinery |

| Designed for Water Supply, Drainage, Heating, Air Conditioning, Water, pH 1÷14 / Glycol solutions / Wastewater with abrasive up to 7% | Designed for pumping syrups, juices and suspensions with temperatures up to 95°C, acidity levels of pH 5.8-13.2 and density up to 1300 kg/m3 | Designed for pumping chemically aggressive and neutral liquids with temperatures up to 95°C, acidity levels of pH 2-13.2 and density up to 1300 kg/m3 | Designed for pumping petroleum products and other liquids with similar physical and chemical properties, with temperatures up to 130°C. For use in explosive industries. |